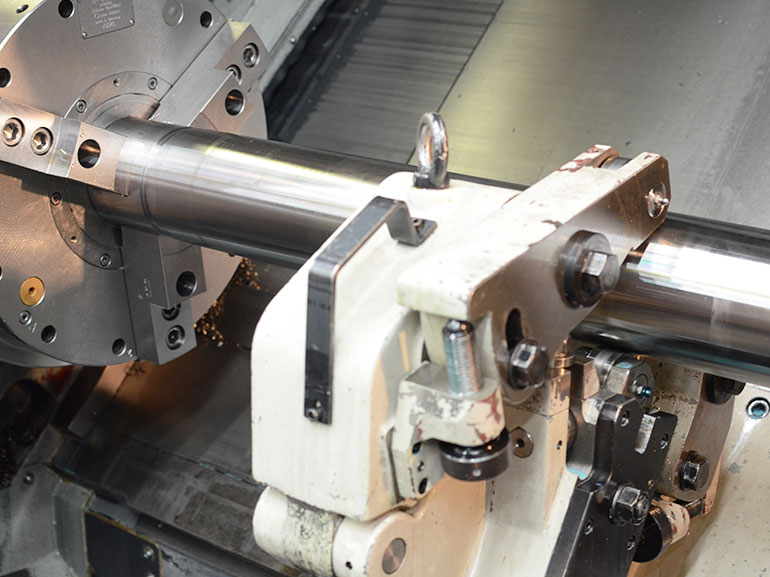

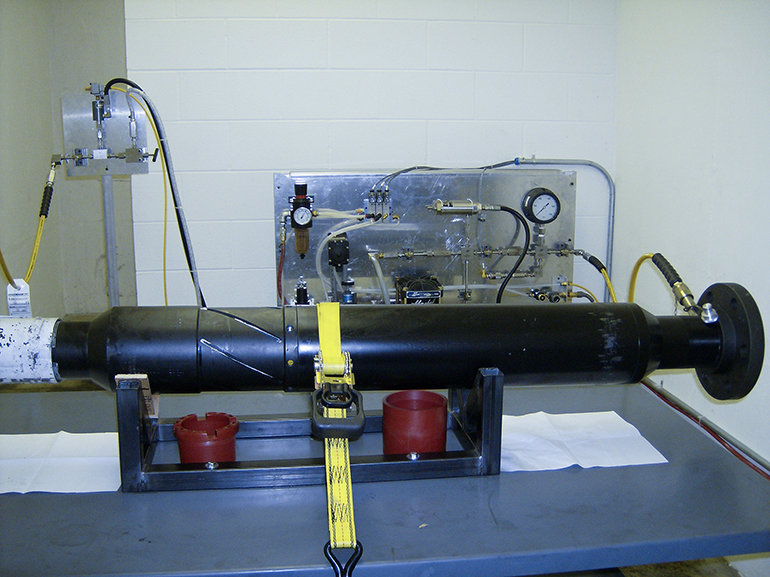

Automation is used throughout our factory to be as efficient and cost-effective as possible. for example, managing KanBan programs offers dock-to-stock commitments that consistently meet customer delivery dates.

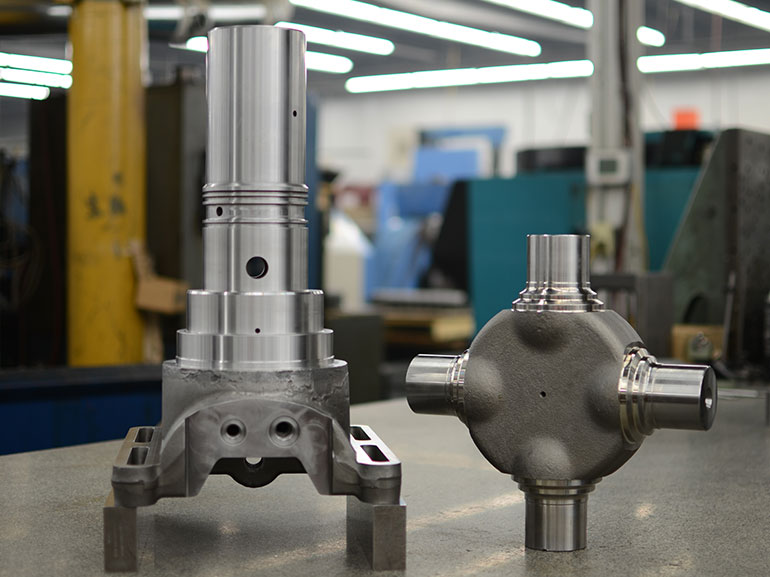

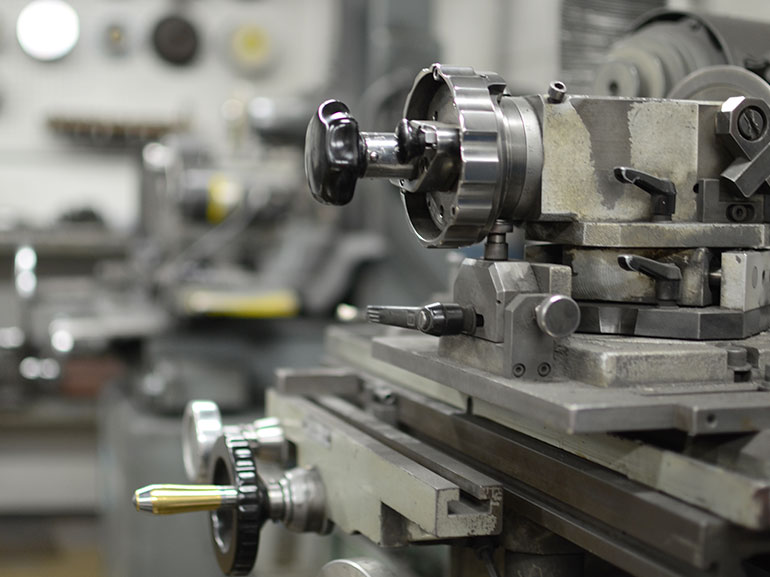

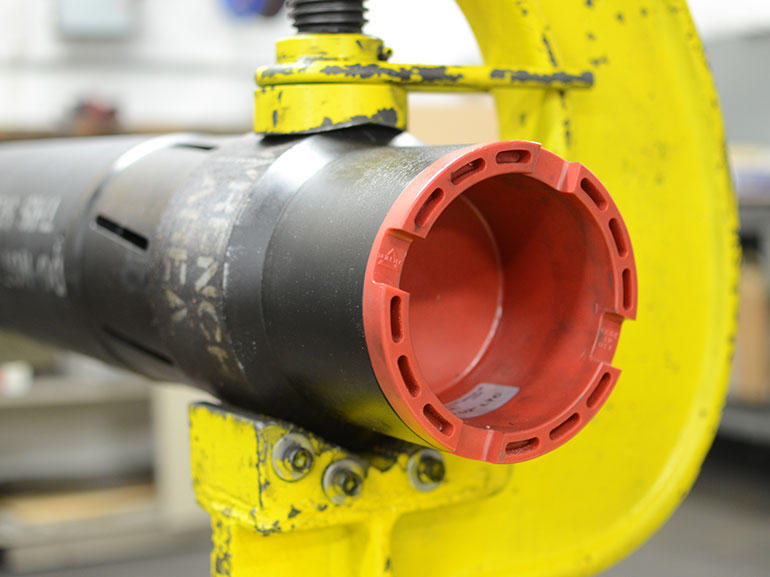

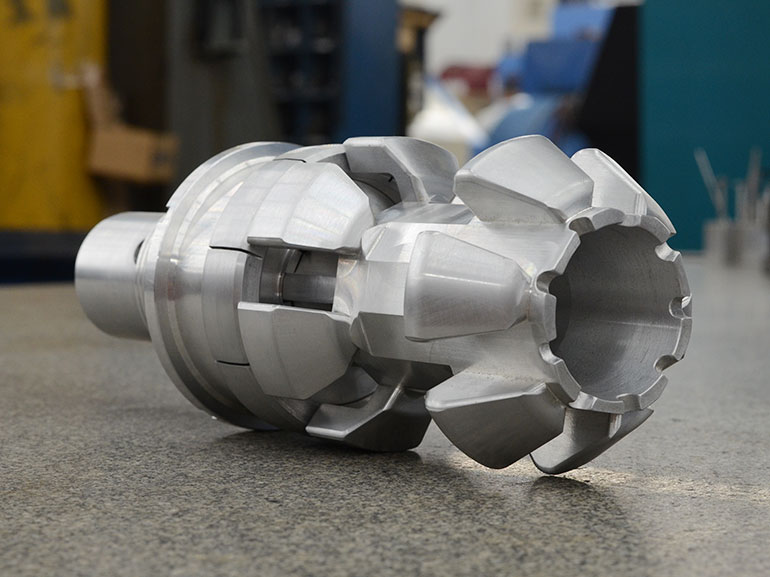

Our CNC manufacturing processes are insured by complete first Article, In-process and final Inspection methods. Constant monitoring of the process ensures repeatability and reliable quality.

Crown Machine Inc. continues to invest in the latest technology in machine tools. We also invest heavily in our people. Our employees receive extensive training in ISO 9001:2008 procedures and work instructions, as well as individualized training relevant to their particular department or machine.